Fully Automatic Wire Cutting Stripping Crimping Twisting Tinning Machine

Automatic Wire-to-Board Connector / Board-to-Board Connector / RJ Jack & Wiring Machine

By your side for a smart restart

We never stopped innovating to make wire processing machines smart again.

Tic put the technology and engineering come together to create high-level machines to make the wire processing works with easy operation, with the benefit of our customers, driving wire processing automation in action.

TC-2017 series - since the year 2017

*1. TC-2017CT 5 wires Cut strip Crimp & Tin machine (Max. 3 - 10 meters)

*2. TC-2017CTS AWG #16 Cut strip Crimp & Tin machine

*3. TC-2017BC 5 wires Cut strip Both End Crimp machine

*4. TC-2017BT 5 - 15 wires Cut strip & Both Ends Tin machine (Min. 14 mm)

*6. TC-2017BCF Flat Cable Cut/Strip/Split & Crimp on both ends. (Upside Down Adjustable).

*7.TC-2017CTB 5 wires Both Ends Crimp + Crimp & Tin machine 2-IN-1

*8. TC-2017CTBT 5 wires Crimp & Tin + Both Ends Tin machine 2-IN-1

* TC-2022C wire-to-board connector machine

'Multi-Function Machine - Using the Japanese Taiwan China parts - High performance - Accuracy - Durable - Easy maintenance - Easily replace the renewed parts. - Purchasing machine equipment is easy work'

TC-2017CT / TC-2017CTB / TC-2020 / TC-2020S machine '5 - 12 wires'

TC-2017CT10M for 10 meters wire - 5 wires prcessing

TC-2017CTS AWG #16 Wire Cut/Strip/Crimp & Tin Machine

TC-2017CTB : 2-IN-1 Machine 'Both ends Crimping + 1 end Crimp/1 end Tin' (Max. 3M in wire lenght AWG #22 - #30)

Both ends Crimping - AWG #30

TC-2017 Automation machine series. TC-2017

- We help you master the science of fastening -

The automation level up of wire processing works.

Crimping & Half-Stripping function

TC-2017BT 10 wire Cut / Strip / Twist & Tin on the Both Ends Machine

TC-2017BT : 1 - 15 wires Cut Strip & Both Ends Tin Machine (15 wires - order-made)

High Accuracy - 14 mm & 20 mm short wire,

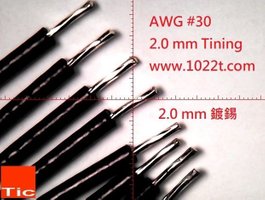

2 mm tin on both end #28 UL1061 / #30 AWG,

14 mm / 20mm in length

#TC-2020 #TC-2017CT/BC #TC-2017BT/CBT :

5 machines

AWG #30 2.0 mm Tinning

- How to send inquiry?

* TC-2020 /TC-2020S wire to board Connector & Tin

* TC-2017CT 5 wires Cut strip Crimp & Tin machine

* TC-2017BC 2 Ends Crimp

* TC-2017BT 5 - 15 wires Cut strip & Both Ends Tin

* TC-2017CTB 5 wires Both Ends Crimp + Crimp

/ Tin machine 2-IN-1

* TC-2017CTBT Crimp & Tin + 2 Ends Tin

* Automation manufacturing your wire harness.

* We design your machine to work for you.

* Machines are using Japan/Taiwan/

China's top brand of automatic parts & devices.

* Time Saving / Manpower Saving / Less managing

Cost

* 1 machine to built up a new business -

2-IN-1 Machine #TC-2017CTB :

2 Ends Crimping + 1 End Crimp & 1 End Soldering

Share this page

'2-IN-1 machine :

'5 wires Both ends Crimping & 1 end crimping / 1 end tinning'

#TC-2017CTB 'Multi-Function Machine'

*Using the Japanese parts /Taiwan /China parts

*High performance

*Accuracy *Durable

*Easy maintenance

*Easy replace the renewed parts.

2-IN-1 Machine #TC-2017CTBT :

5 wires Crimping & Tinning + 2 Ends Tinning

5 wires Cut / Strip / Crimp / Tin or Both end Tin machine / Both Crimp machines

3 machines at customer's workshop

Easy operation with high end performance to bring the good wires orders.

TC-2017CT 5 WIRES CRIMPING AND TINNING MACHINE

Model: TC-2017 series

5 Wires Proceeding at 1 time - Time Saving / Manpower Saving / Increasing profit for your company on Wire Harnesses & Cable Assemblies.

Choose your own machine to work for you.

Level Up Your Machine.

- Top Level Engineering Design -

- Stable & Durable & Accuracy -

- Optimization of manufacturing -

- Automation Technology -

- Benefits automatically increase -

- Machine maintenance easily -

TC-2020 : Wire to Board Assembly & Tinning machine.

Model: TC-2020

2 - 12 pins Wire to Board Connector & Tinning machine: Auto Wire crimping & Inserting into Housing connector on 1 end, The other end wires with Tinning.

New TC-2023 is available for 2 - 20 pins.

TC-2017CT / TC-2017BT : 1 End crimping & 1 End tinning / 2 Ends Crimping Machine

or 2 ends Tinning Machine

Model : TC-2017

Auto Cut/Strip/Crimp/Tin 4 works with only 1 click. Hundreds of unit machines are used at the different wires assembly factory.

1 TC-2017 machine to set up your "Wire Assembled Department"

5 machines are using at Customer's workshop

4 TC-2017 machines are using at Customer's workshop

TC-2017CT 5 wires Crimping & Tinning machine Short wire crimp & tin

3 TC-2017 machines at Customer's Workshop

2 TC-2017 at Customer's workshop

TC-2017BC 5 wires Cutting/Crimping at both ends

* The 2 crimping on both ends, and 1 end crimping & 1 end stripping - 2 in 1 Machine

TC-2017CTB : 2 Ends Crimping TC-2017CT : 1 End Crimp & 1 End Tin

+ 1 End Crimping & 1 End Tinning

2-IN-1 Multi-function Machine' -

TC-2017CT Crimping & Tinning machine

TC-2017BT 5 wires Both ends Tinning machine

Automatic Cutting & Stripping & Tinning on Both Ends.

TC-2017BT available for 5 - 15 wires. (Order - Made)

TC-2017CT Super Short wire & Long Wire

TC-2017CT Crimping and Tinning machine

Tiny short wire processing mode machine operation, long wire processing mode machine operation.

5 Short wires processing: Cut / strip/ twist / crimp /tin at 1 time. Long wire processing is also available. max. 2 M

Production Equipment : CNC machine center

Automation manufacturing the TC-2017/TC-2020 machine accuracy parts.

Our high-end CNC Machine Centers make our accurate mechanical parts.

We design and manufacture high-accuracy and durable mechanical parts. The level up by our engineering dept. all the artworks by our professional engineer's team.

About us :

-1. Tic Group member, which it is a 28 years machine manufacturer & Exporter from Keelung -Taiwan since 1994.

-2. After years of experience/machine producing knowledge, our design house has been released TC-2017 at the market since 2016, This is our newly developed machine series which has selected by many wire processing /wires harness assembly factories since Nov. 2016, many Clients have been using their 2nd to 10th TC-2017 machine at their production line, TC-2017 is really an Innovation High-end machine with Mercedes level. But, it comes with very competitive pricing with our top-level/excellent design.

-3. Our Design and R&D & Manufacturing engineer team with professional technology to provide the new development skills of artwork to meet customers' expectations. Ingenious development is Our hallmark to keep us always ahead in the field.

-4. We are good at English speaking along with English communication skills & documentation.

-5. Re: TC-2017 / TC-2020 Order Payment Terms

We offer the very best payment terms on your initial order of our TC-2017/TC-2020, along with 100% unique quality guarantee. Payment terms : Can be negotiable.

It’s not what we think about TC-2017/TC-2020, it’s what our customers and the industry think about the TC-2017/TC-2020. That’s why we are the leading machine for the 5 wires processing machine.

Through our teamwork, we can assure customers that we always offer HIGH-PERFORMANCE UPDATE QUALITY at a very competitive price with reliable service. Machine purchasing is 1 of the easy works.

____________________________________________

Built for speed. Primed for performance & accurancy.

Developement & Update :

Tops-mate International Corporation

No.9-10, Lane 77, Tong Ming Rd., 20141 Keelung, Taiwan

T. +886-2-2468-0709 F. +886-2-2465-0401

e. topsmate@mail2000.com.tw

The other new devices/equipment to enhance high-end machine character, And to support machine operator with easy work, All these new items will be listed on inquiry and quotation, Please inform your machine need, We will make your machine to work for you. All machine innovation development has been done by our teamwork design house, The new update machine to create the machine revolution. How to Create an Effective & Simple Machine Compliance Program design is 1 of our goals.